OUR WORK

Production process

What truly sets us apart at NUMBER ONE LS is the way we approach every project.

We see each yacht as a unique canvas, and we collaborate closely with our clients to bring their visions to life.

Whether we’re designing a bold, statement-making logo for a new superyacht or creating elegant, subtle lettering for a classic sailing yacht, our approach is always meticulous, thoughtful, and personal.

“Crafting excellence: where creativity meets precision.”

Easily adjustable brightness to create the perfect ambiance.

Seamlessly integrates with existing lighting systems on board for easy control and customization.

Tailored to suit specific installation requirements for a clean and organized setup.

Durable and reliable, designed to withstand harsh conditions while providing consistent, long-lasting performance.

A wide range of colors to suit any design preference, with the option for dynamic color-changing effects.

Flexible design options to meet the unique specifications of each project.

Provides a smooth, even light output without any distracting spots, ensuring a clean and professional appearance.

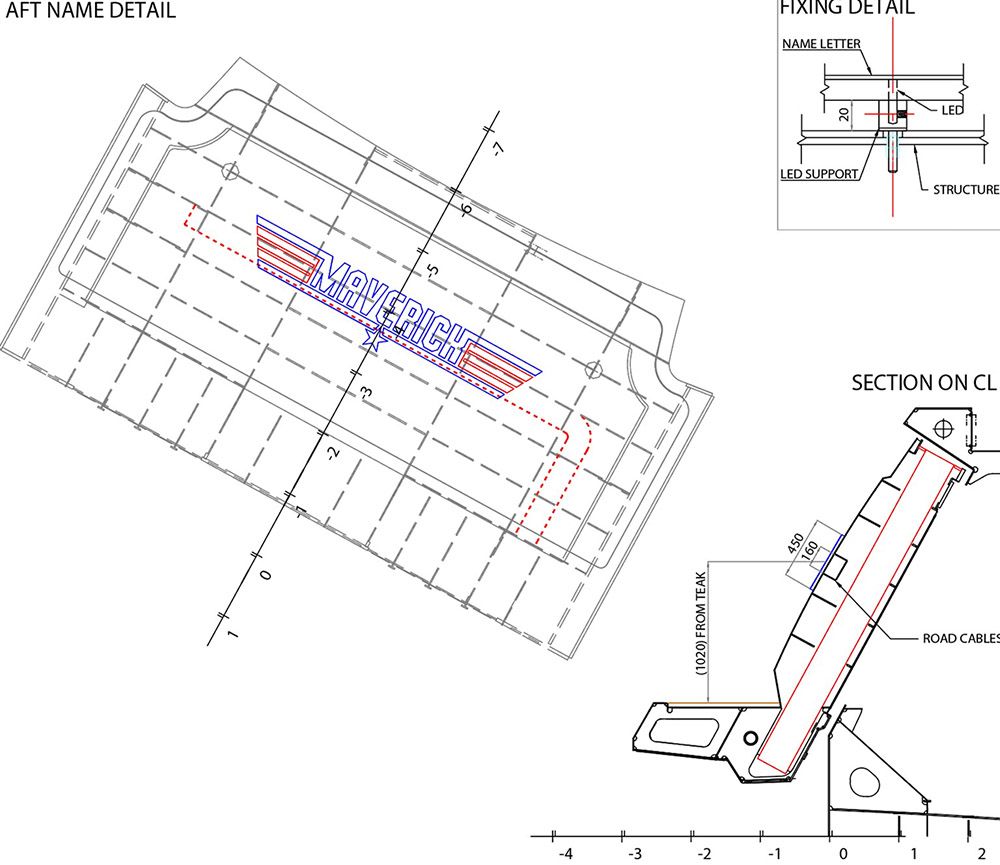

DESIGN

We believe in the power of creativity.

Our designs are not only functional but also serve as an artistic expression of each yacht’s identity.

The attention to the details is the priority, from the choice of materials to the precision of the craftsmanship, we ensure every detail is executed flawlessly.

It’s this dedication to excellence that has earned us a reputation for quality and reliability. Our team is made up of skilled artisans and designers who take great pride in their work. We are passionate about every project.

3 step of

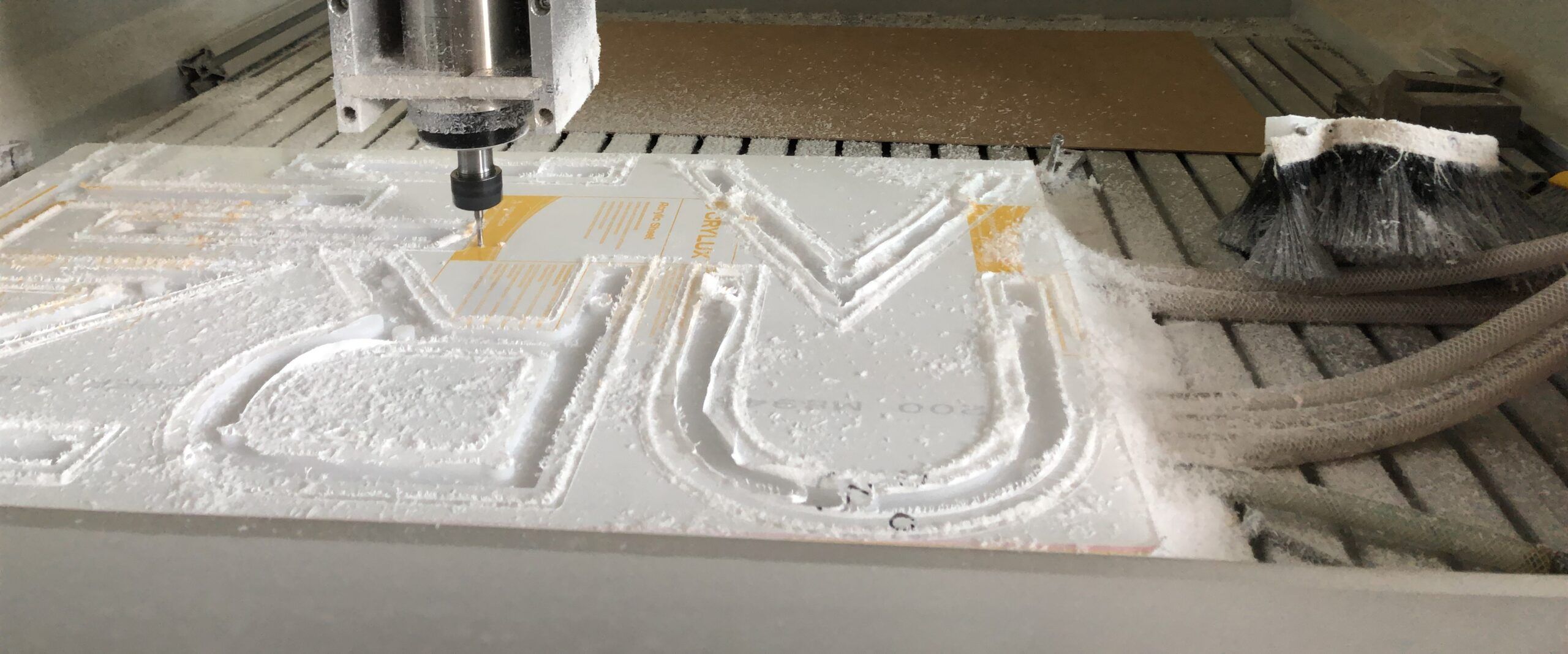

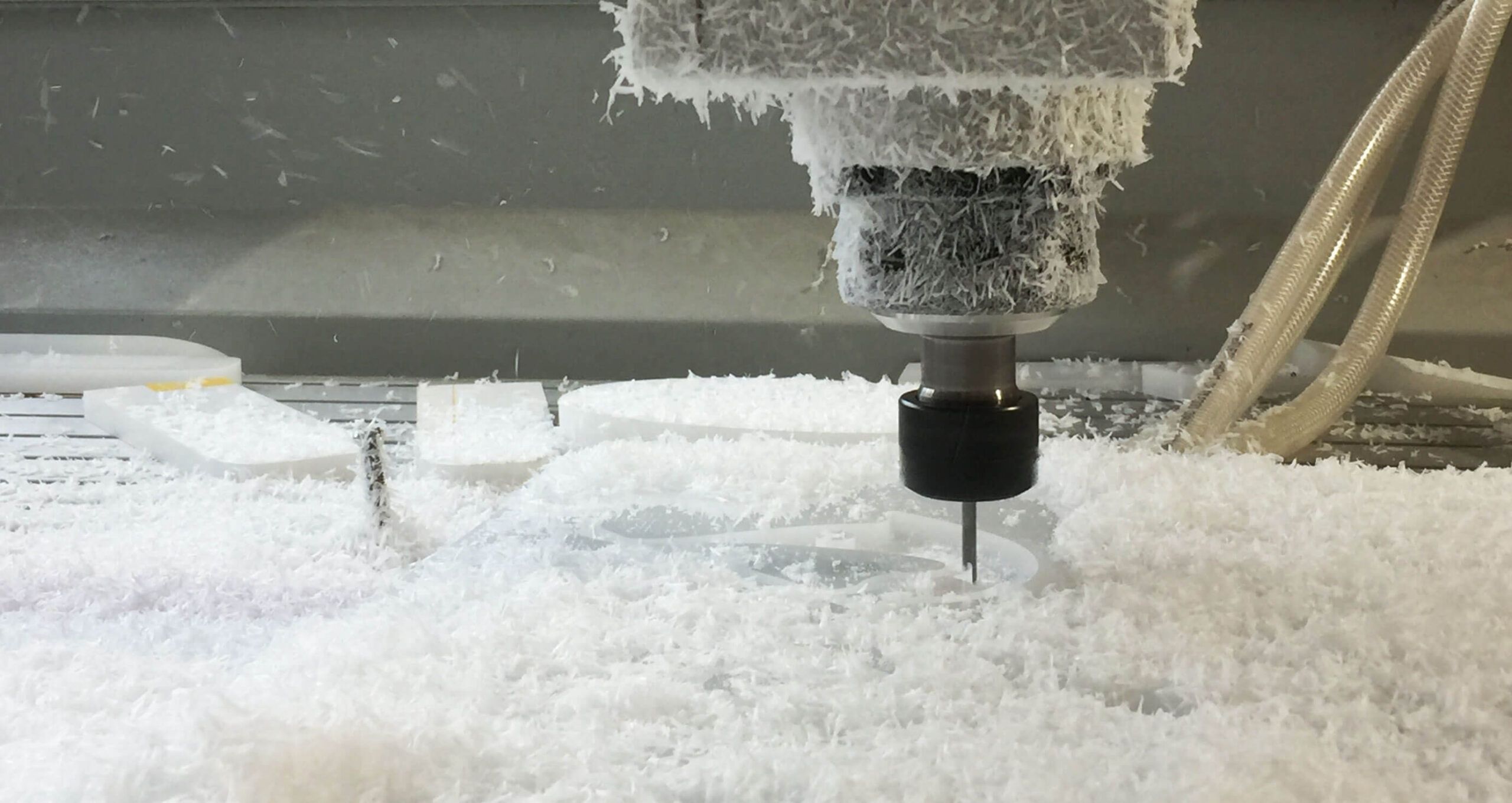

OPAL

PROCESSING

1

The use of UV-resistant, premium-quality acrylic ensures long-lasting durability and prevents discoloration over time, maintaining consistent performance and visual appeal even under prolonged exposure to sunlight.

2

The 12mm (or 15mm) satin-finished acrylic is precisely cut using high-precision machinery.

3

The precise cutting ensures flawless edges and exact dimensions, providing superior quality and a refined finish for every piece.

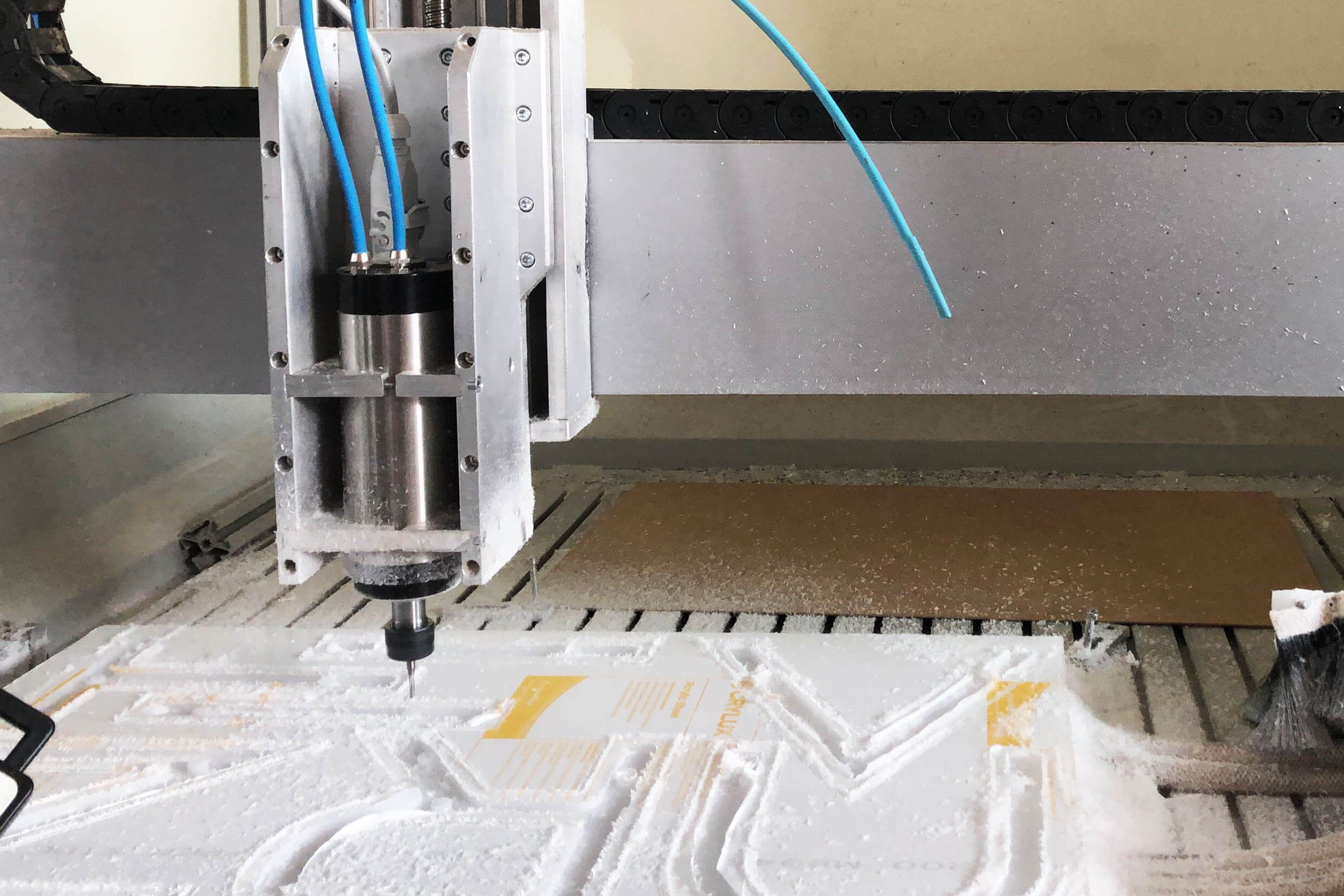

STEEL

PROCESSING

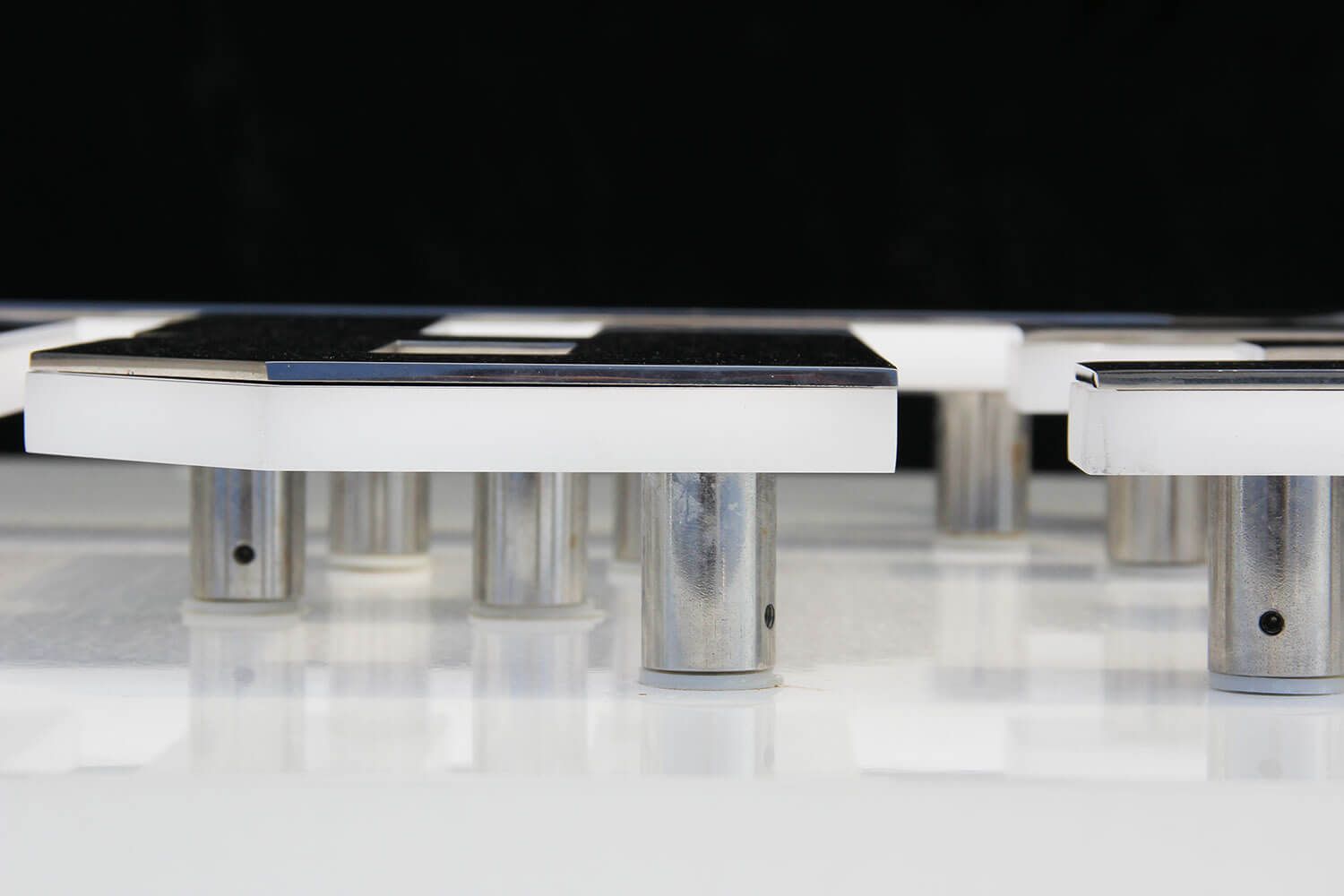

To achieve a precise fit, advanced CNC milling machines and state-of-the-art laser cutting technology are employed.

These cutting-edge tools ensure exceptional accuracy, allowing for the creation of perfectly tailored components with unparalleled precision.

Using premium-grade materials like AISI 316L stainless steel, each piece is meticulously crafted with smooth, flawless edges and consistent dimensions that adhere to the most stringent quality and craftsmanship standards.

This level of precision not only enhances functionality but also elevates the aesthetic appeal of each component.

The process is completed with the meticulous polishing of the steel, a task entrusted to the skilled hands of expert craftsmen. These artisans, masters of a timeless art, bring their deep expertise and attention to detail to every piece, ensuring a lustrous, mirror-like finish that highlights the inherent beauty and durability of the material.

The result is a perfect blend of modern technology and traditional craftsmanship, creating components that are as functional as they are exquisite.

HAVE YOU EVER HEARD THAT…

Stainless Steel:

Tips for Longevity and Shine

To make each project timeless, it is important to dedicate careful cleaning and maintenance efforts to prevent and counteract corrosion and the buildup of carbonate.

Since the shine of stainless steel is not eternal, it is strongly recommended to rinse the steel with fresh water several times a day, especially if it has been immersed in saltwater. In addition, it is very important to treat it with chrome pastes to maintain its lustre.

By doing so, you help reduce the buildup of calcium carbonate, ensuring that the steel remains in perfect condition.

Finally, special attention should be given to harmful products for the steel:

- Hydrochloric acid

- Sulfuric acid

- Hydrofluoric acid

- Calcium hypochlorite

- Sodium bisulfate

FIXING

The assembly of the processed materials is carried out only after a thorough quality assessment of the finished product.

Each component is meticulously aligned and expertly assembled using precise gluing, screwing, and coupling techniques. This careful process ensures a seamless integration of parts, resulting in a cohesive and durable single structure that meets the highest standards of excellence.

The highly specialized staff of NUMBER ONE LS provides a complete and turnkey service, taking care of every aspect of the project, including assembly on board. This is done in collaboration with architects and designers, ensuring a perfect integration between aesthetics and functionality.

During the design phase, an in-depth study of the assembly is conducted to verify its feasibility to avoid any critical issues.

This proactive approach allows you to optimize time and resources, ensuring that the final step of the assembly process runs smoothly, with flawless results that meet the highest standards of quality and precision.